|

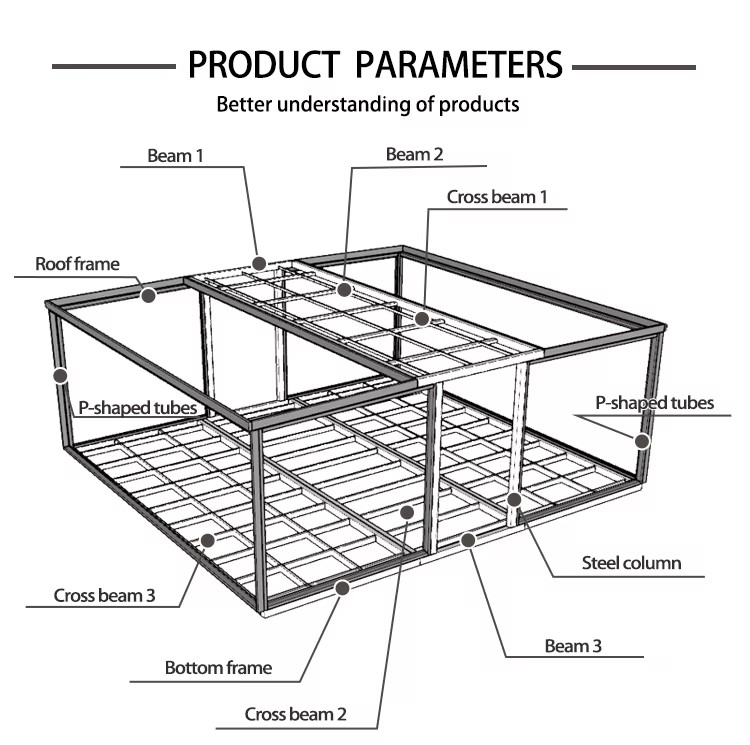

Structure

|

|

No.

|

Name

|

Content

|

Specifications

|

|

1

|

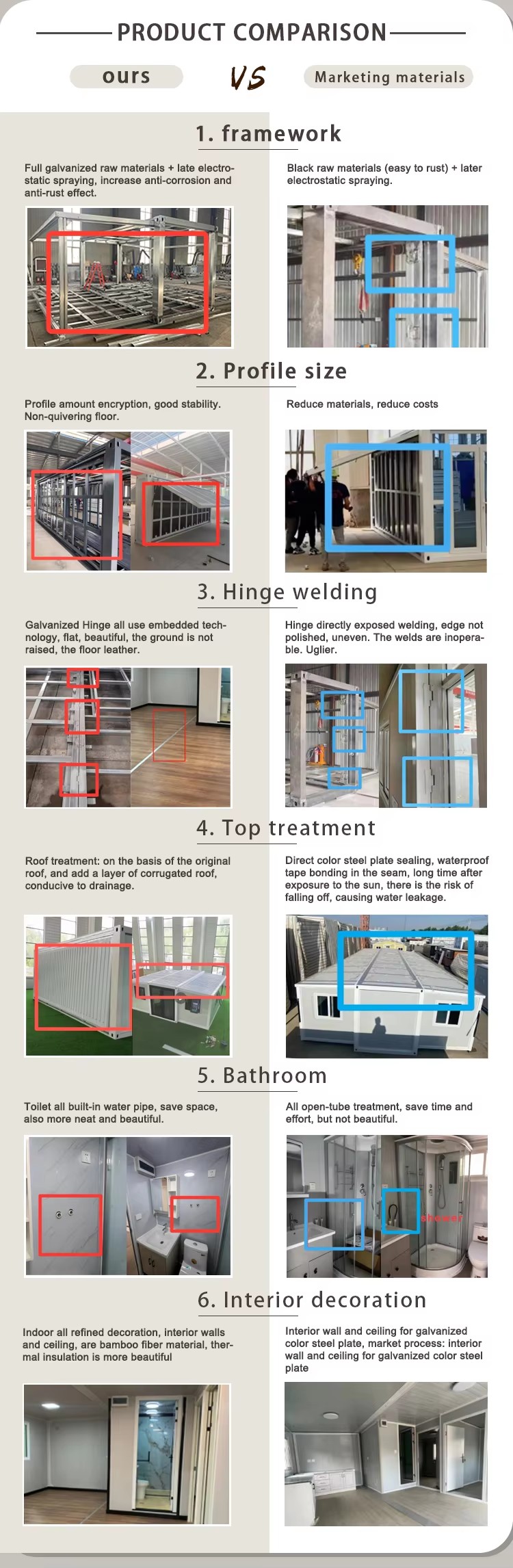

Main frame (full galvanized national standard)

|

Top side beam

|

Square steel pipe 80*100*2.5mm galvanized

|

|

2

|

Top beam

|

Galvanized bending parts 2.5mm

|

|

3

|

Top horizontal secondary beam

|

口30*50*1.8mm Zinc-plated square tube

|

|

4

|

Sideshaft

|

Square steel pipe 80*100*2.5mm galvanized

|

|

5

|

Bottom beam

|

Galvanized bending parts 2.5mm thick

|

|

6

|

Bottom longitudinal secondary beam

|

口40*80*1.8mm Zinc-plated square tube

|

|

7

|

Secondary horizontal beam at the bottom

|

口40*80*1.8mm Zinc-plated square tube

|

|

8

|

6mm galvanized ceiling fixing

|

Zinc-plated ceiling L210*W150*H160mm

|

|

9

|

Steel column

|

Galvanized bending parts 2.5mm thick

|

|

10

|

Side frame (full galvanized national standard)

|

Top frame

|

P40*80*1.8mm P-shaped pipe

|

|

11

|

Square steel tube 40*80*1.8mm galvanized

|

|

12

|

Base frame

|

Square tube 60*80*2.0mm galvanized

|

|

Thirteen

|

Folded hinge

|

130mm galvanized hinge

|

|

14

|

Overall framework protection coating

|

Spray paint baking

|

Electrostatic spraying + anti-corrosion treatment (fluorocarbon baked paint)

|

|

15

|

Top of the box

|

Main ceiling panel + external ceiling

|

Double-sided 0.3mm, double 50EPS color steel composite board + nano insulation board

|

|

16

|

top plate

|

65mm thick double-sided 0.3mm, graphite EPS composite board + nano insulation board

|

|

18

|

skeleton

|

Polishing process: Polishing treatment is carried out after overall welding, the plastic powder is more even, and the service life is increased.

|

|

19

|

|

40*80 nine horizontal and two vertical: increase the stability of the bottom, no shaking when walking

|

|

|

20

|

|

Cutting, forming, drilling, welding and corrosion protection of steel structures all meet the CE certification of the EU.

|

|

|

21

|

Floor decoration panel

|

Base plate: bamboo plywood 18mm thick

Decorative floor: SPC stone plastic floor 4.0mm

(color optional)

|

|

22

|

Door

|

Inner room door

|

High-end aluminum-wood doors*2 sets

(size: 750*2075mm)

|

|

23

|

Entrance door

|

Aluminum double door with broken bridge*1 set

(size: 1895*2235mm)

|

|

24

|

Window

|

Broken Bridge Aluminum Horizontal Windows: 1200*1200mm*4 sets

Broken Bridge Aluminum Casement Windows 500*1000*2 sets

(Including 6 sets of diamond window screen)

Double-layer Tempered Glass

|

|

25

|

Electrical system

|

Circuit system

|

Voltage 220V, 50HZ

|

|

26

|

Lighting

|

300*600 panel light, large ceiling light

|

|

27

|

Socket

|

Standard international three-hole, five-hole sockets (socket standard can be configured according to customer requirements)

|

|

28

|

Light switch

|

Double throw, single pole switch (switch standard can be configured according to customer requirements)

|

|

29

|

Wiring

|

6㎡ incoming line, 4㎡ air conditioning socket, 2.52 ordinary sockets, 1.52 lighting (standard national standard wires, circuit can be customized according to the country to meet the certification requirements)

|

|

30

|

Accessories

|

Includes top angle line, skirting board, corner wrapping, waterproof tape, hangers, structural glue (white cloud), glue gun, etc.

|